As environmental awareness increases, more and more brands and consumers are paying attention to the application of sustainable materials to reduce the burden on the environment. Recycled Polyurethane (Recycled PU) is one of the eco-friendly materials that has attracted widespread attention, especially in the backpack industry, where more and more companies and designers are choosing it to produce their products.

What is Recycled PU?

Recycled PU, also known as recycled polyurethane, is made from recycled PU materials (such as production waste or discarded items) through processing and regeneration. Typically, these PU waste materials go through processes such as crushing, melting, and reshaping to be turned into reusable polyurethane raw materials. This process not only reduces waste generation but also decreases the dependence on new resources.

|

|

Recycled PU not only retains the softness, wear resistance, and waterproof advantages of traditional PU but also has a more environmentally friendly production process. Therefore, recycled PU, which combines environmental protection and high performance, is an important material for the fashion and luggage industry to achieve sustainable development goals.

Main Features of Recycled PU

Environmentally Friendly: The production process of recycled PU uses recycled materials, reducing the exploitation of natural resources. This not only lowers the carbon footprint but also reduces the accumulation of PU materials in the natural environment.

High Durability: Recycled PU materials, after modification treatment, maintain excellent tensile and tear resistance, making them very suitable for the frequent use and wear of daily backpack products.

Waterproof and Easy to Clean: Similar to traditional PU, recycled PU has good waterproof performance, making it highly valuable in outdoor backpacks and sports bags. In addition, its surface is easy to clean, facilitating daily maintenance.

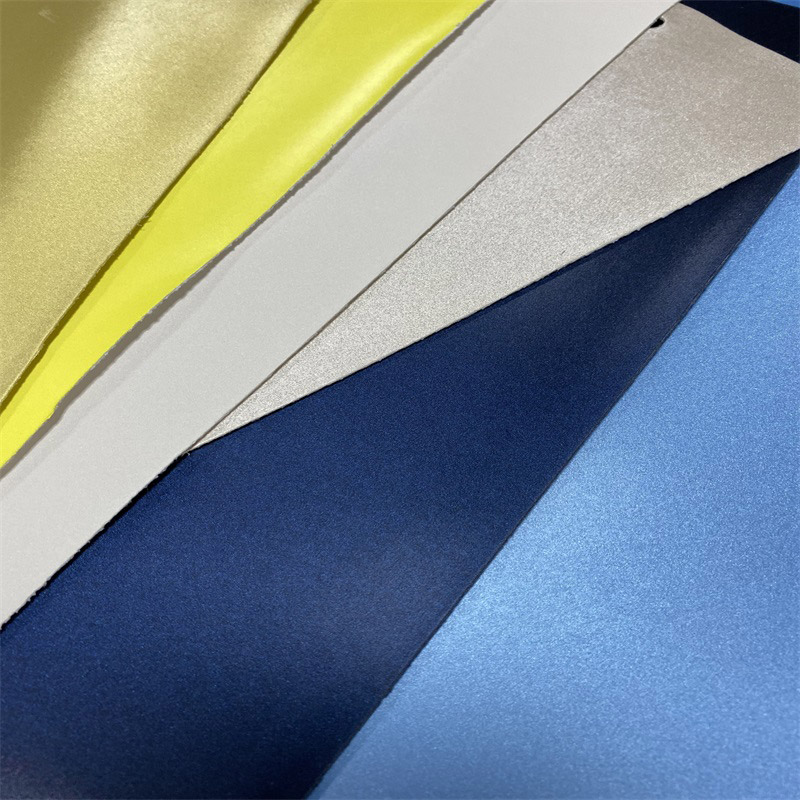

Diversity and Design Flexibility: Recycled PU can be customized in different thicknesses, textures, and colors, allowing for a variety of styles and design options, enriching the appearance choices for backpacks.

The Production Process of Recycled PU

1.Collection and Sorting: Producers collect waste PU from post-consumer or industrial waste and sort it.

2.Crushing and Melting: The sorted PU waste is crushed and then melted to be reshaped at high temperatures.

3.Filtering and Treatment: Chemical treatment is used to remove impurities and maintain the stable performance of the PU material.

4.Reshaping and Processing: Finally, the material is reshaped into films or fabrics for production, creating the recycled PU materials we are familiar with.

This production method is more energy-saving and environmentally friendly than synthetic PU materials, and it also reduces the dependence on chemicals.

Why Choose Recycled PU?

For brands and consumers who focus on environmental protection and social responsibility, recycled PU represents a forward-looking choice. It not only reduces material waste and environmental pollution but also provides a sustainable alternative to traditional materials. Synberry is well aware of the importance of environmental protection to the industry, and we are committed to continuously introducing more recycled PU materials into our future backpack products, making every backpack a contributor to the protection of the Earth's resources.

Copyright @2024 Synberry Bag & Package Products Co.,Ltd All Rights Reserved.

Network Supported

Network Supported

Sitemap / Blog / Xml / Privacy Policy